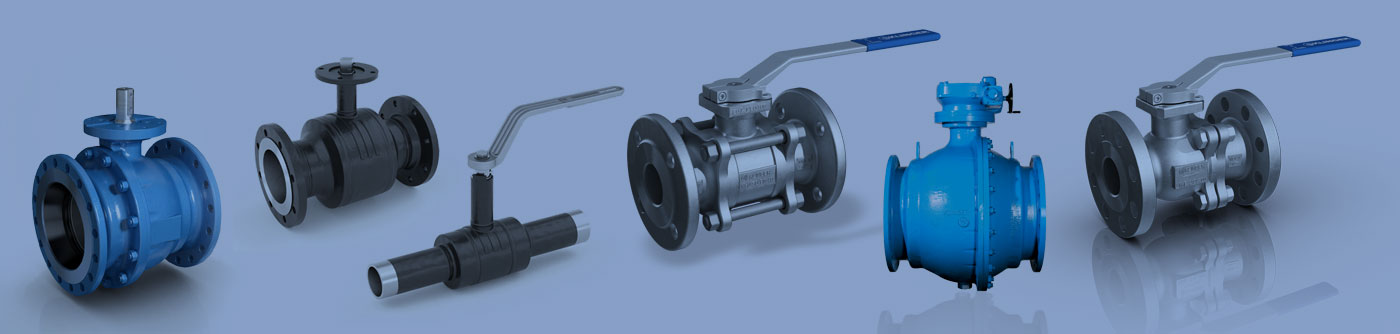

INTEC Series High Pressure Ball Valves

KLINGER High-pressure ball valves of the modular INTEC system technology!

Industrial ball valves are important components in process engineering systems of all main sectors for the maintenance of transport and production processes. The various applications require shutting off, throttling and regulating material flows (solid-containing, liquid or gaseous) in piping systems up to opening and closing processes in piping systems.

KLINGER have employed their detailed technical knowledge and application experience for the differentiated design and manufacturing of the industrial ball valves to effectively manage the occasional extreme operating conditions (pressure, temperature, medium) as well as safety requirements.

KLINGER range of INTEC high pressure ball valves

Flanged ball valves (2-pcs.)

MoreWafer type ball valves

MoreMultiple way ball balves

MorePressure gauge ball valves

MoreHigh pressure ball valves (3-pcs.)

MoreINTEC Ball Valves – Highlights

High precision bearings, with single or both sides spring loaded seat ring elements, are responsible for safe handling in all applications of the high-pressure ranges.

- Equipped with all advantages of series INTEC K200.

- Two-piece split body or three-piece split body design.

- Extreme long-life acc. high precision bearing of the stem.

- Optimized arrangement of the bearing forces.

End connections / Face to face dimensions

DIN design: FTF dimensions acc. to EN 558, GR.1, GR.2, GR.27 / Flanges acc. to EN 1092

ANSI design: FTF dimensions acc. to ANSI B 16.10 / Flanges acc. to ANSI B 16.5

Materials

Stainless steel, Carbon steel and special materials like Duplex, Super Duplex, Hastelloy B2/C4/C276, Titanium, Zirconium, Monell, Nickel etc.

Product Approvals

- Certificate TA-Luft VDI2440INTEC high-temperature 325bar eng

- TA-Luft VDI-2440 INTEC STD 325bar eng

- ATEX Bescheinigung Declaration INTEC

- TA-Luft VDI2440 INTEC-STD deu

- TA-Luft VDI2440 INTEC Fire Safe eng

- Fire Safe ISO INTEC-K200series INTEC-112series eng

- Declaration Conformity INTEC-Module-H eng

Go to Product Approvals

Other Ball Valves

Rugged construction, used in many industries.

MoreFlanged ended valves – perfect for effective control of Oil and Gas piping.

MoreGeneral Information

The specified pressure and temperature values showing the maximum range for orientation only. For the necessary design please note the pT diagram in the respective data sheet. Main criterion of the material code is the basic material of body and cap. The performance and service life of KLINGER valves depend largely on proper storage and fitting – factors beyond the manufacture’s control. We can, however, vouch for the excellent quality of our products.

Related Products from KLINGER

KLINGER offers valve actuators as well as actuator accessories, including pneumatic actuators, electric actuators, solenoid valves and limit switches.

MoreAn efficient process operation demands high-performance measurement equipment.

More