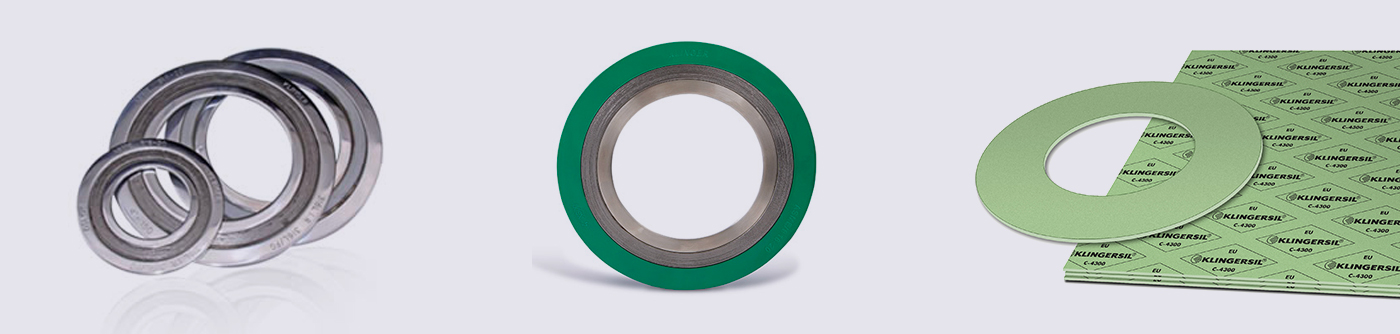

KLINGER Metallic Gaskets

Gaskets that handle most aggressive chemicals

KLINGER metallic gaskets, along with the older style jacketed gaskets are widely used in petrochemical applications. Metallic gaskets often utilize a soft sealing medium such as graphite in conjunction with the metal to create a high-strength, high-integrity gasket. This results in joints with very high leak-tightness.

KLINGER manufactures metallic gaskets in a wide range of alloys to cover even the most chemically aggressive applications.

Metallic Gasket Facts

- Spiral wound gaskets: Ideal for use in applications where thermal cycling can be a problem.

- Kammprofile gaskets: combine the benefits of a soft material with the advantage of high integrity sealing of a metal gasket.

- Corrugated gaskets: particularly suitable for applications involving narrow flanges.

- Ring type joints: mainly used in offshore applications and certain styles can be adapted for subsea installation.