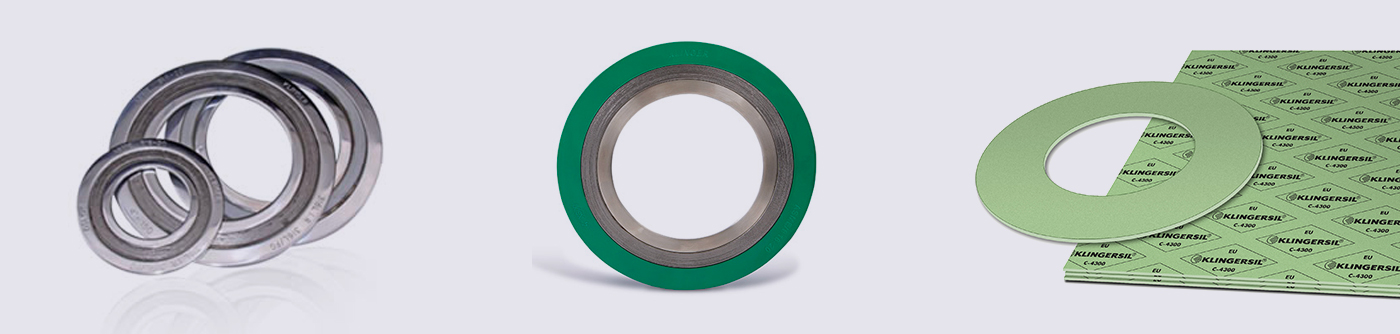

KLINGER Gaskets and Seals

Our complete range of gaskets for all applications

As the world’s leading manufacturer and provider of industrial sealing materials, KLINGER’s product portfolio of gaskets is at the forefront of sealing technologies.

Wherever fluids or gases must be safely contained in pipelines and vessels, gaskets manufactured directly by KLINGER or gaskets from KLINGER Materials are to be found in industries around the world. Our gaskets ensure reliable and safe operation – without leakages and subsequent harm or material damage.

Our operating philosophy has been to create product excellence based on research, product development, innovation and problem-solving abilities; thus offering gaskets to industry in India, constructed using revolutionary materials for every thermal, mechanical, and chemical resistance.

Development of the compressed fibre gasket or the Polystrat rubber coated steel are advanced sealing material technology of today, providing state-of-the-art solutions for serious applications.

CNAF (Compressed Non-Asbestos Fibre) gaskets, constructed from high quality sealing materials reinforced with glass fibre, carbon fibre or aramid fibre provide excellent resistances (e.g. temperature, mechanical or chemical resistance) in the areas required by the corresponding target industry.

More

Soft sealing material gaskets based on PTFE guarantees maximum chemical resistance and is designed to satisfy most gasket applications. These gaskets seal even at low surface pressures, offer high resistance against strong acids or alkaline solutions, and support medium and low temperatures.

More

Graphite-based gaskets are suitable for temperatures between -200 °C and up to 550 °C and offer resistance against a wide range of chemical products. Equipped with a non-stick finish, it is easily removable from the flange, even after exposure to high temperatures.

More

KLINGER manufactures metallic gaskets in a broad range of alloys, often utilizing a soft sealing medium such as graphite in conjunction with the metal creating a high strength, high integrity gasket to cover even the most chemically aggressive applications. Widely used in petrochemical applications.

More

Rubber-steel gaskets (KGS) comprise the rubber types NBR, EPDM. Employed for safe sealing of either conventional or special industrial media, either in the form of liquids or gases, they can be used in combination with all types of flange materials, ranging from plastic to steel.

More

KLINGER Sealex, Compression Packing and Insulation Sets are the add-ons to seal gaskets effectively on joints, to protect flange faces, stud bolts and gaskets from corrosion, or to pack valves, rotary and reciprocating pumps with the right material.

More